Línea de producción totalmente automática de pellets de alimentación para gatos, perros y mascotas

| Aplicación |

Precio de fábrica máquina flotante de pellets para piensos para peces, ganado, perro |

| Materia prima |

el maíz, el trigo, etc. |

| Puntos de venta clave |

Alto nivel de seguridad |

Descripción del producto

La línea de producción de piensos para peces es un equipo automatizado especialmente utilizado para la acuicultura de peces, camarones, peces ornamentales, etc.nutrición rica y textura delicada mediante el ajuste de los parámetros del proceso tales como las materias primas, temperatura y humedad.

Ventajas principales

- Resolver el problema de la precipitación rápida y fácil de los piensos tradicionales que contaminan la calidad del agua y utilizar el proceso de inhalación para mejorar la estabilidad del pienso y reducir las pérdidas.

- Apoyar la producción de piensos para múltiples especies de peces (como el bagre, la carpa de hierba, los peces ornamentales) y las mascotas (perros, gatos), y puede personalizar la forma y las propiedades flotantes de las partículas.

Flujo del proceso

Incluye el trituración, mezcla, transporte, soplado de doble tornillo, secado, enfriamiento, cribado y otros vínculos de la materia prima para garantizar que el producto esté altamente maduro y fácilmente digerible.

Tamaño para toda la línea

De acuerdo con el tamaño del terreno y el diseño.

Tamaño del pellete

1 a 12 mm

Capacidad

Entre 5 y 10 t/h

Requisitos para los trabajadores

4-5 personas

Requisitos de envío

Contenedor de 5*40 pies

Ámbito de aplicación

gran fábrica comercial de piensos acuáticos y para mascotas

Detalles del flujo del proceso

1- elevador de cubos - sistema de limpieza de materias primas - silos para trituradoras - trituradora - sistema de pesaje automático de materias primas - sistema de mezclado - segundo sistema de trituraciónSistema de pesaje automático de distribución de materias primas 9.segundo sistema de mezclado 10.extrusor 11.sistema de secado 12.sistema de pantalla -13. máquina de sazonado 14.sistema de enfriamiento 15.sistema de embalaje

Configuración del equipo

El equipo principal incluye una extrusora de doble tornillo, equipos de secado de múltiples capas, sistema de control de temperatura totalmente automático, etc.con una capacidad de recarga superior a 300 W,.

Adoptar tecnología de regulación de velocidad de frecuencia variable para lograr un control preciso de los parámetros y reducir el consumo de energía.

Escenarios aplicables

Aplicable a la cría a gran escala (por ejemplo, peces de estanque, peces marinos) y a la cría de peces ornamentales para satisfacer las necesidades nutricionales de las diferentes etapas de crecimiento (peces jóvenes, peces adultos).

Algunas líneas de producción pueden ampliarse al campo de los alimentos para mascotas, tales como alimentos para perros, alimentos para gatos, etc.

Componentes del proceso

- Sistema de trituración:Reduce el tamaño de las partículas de las materias primas y aumenta su superficie específica, mejorando la calidad del procesamiento y la eficiencia del trabajo.

- Elevador de tornillo:Se utiliza principalmente para el transporte de materiales en polvo, granulares y de pequeños bloques.

- Mezclador de materias primas:Mezcla ingredientes y nutrientes para una nutrición equilibrada.

- ¿ Qué pasa?Equipo de transporte de materiales para transporte horizontal e inclinado.

- Extrusor de alimentación:Equipo clave para el procesamiento de los piensos extrudidos mediante extrusión por tornillo.

- El secador:Reduce el contenido de humedad para mejorar la estabilidad y la vida útil.

- Convector de viento:Utiliza el aire como medio de transporte en tuberías cerradas.

- Máquina de condimento de tambor:Equipo de acero inoxidable para condimentos automáticos de piensos.

- Enfriador de contraflujo:Se enfría en capas con un efecto de enfriamiento significativo.

- Silos:Almacena alimentos a granel y protege de la humedad, el moho y las plagas.

Presentación del producto terminado

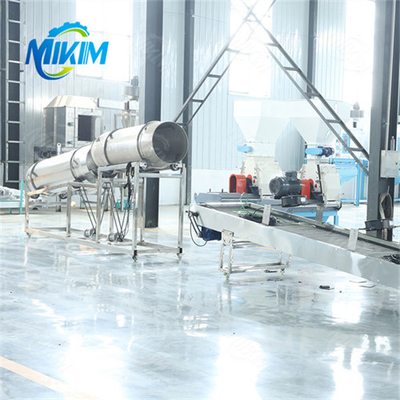

Fotografías del equipo

Certificado de Honor

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!